Highly reflective, highly resistant mirror coatings

Metallic Mirror & High Reflectivity (HR) Coatings

Achieving greater reflectance through optical thin-film technology, such as the coating of glass and resin substrate surfaces with silver, aluminum and other reflective metals

Overview

Since its founding, Geomatec has spent a half century creating metallic mirror coatings (optical mirrors). When it comes to the manufacture of mirrors that require high reflectance and superior optical characteristics, such as those used in video projectors, liquid crystal displays, astronomical telescopes, and other products, Geomatec has extensive experience with metallic mirror and high reflectivity (HR) coatings, so please feel free to seek our advice.

Features & Strengths

Point1 Depending on your needs, we will propose a reflective coating that utilizes the characteristics of aluminum, silver, gold, or other metals

Aluminum (Al) is popular for use in mirrors of visible and infrared varieties, while alloys exist of gold (Au) and silver (Ag) that improve durability and secondary workability. Geomatec has extensive experience with metallic mirror and high reflectivity (HR) coatings, enabling us to propose a variety of metals that meet your objectives.

Point2 Customization of optical or electrical characteristics, or of durability within specific usage environments, is possible

By pairing a variety of metallic mirror and high reflectivity (HR) coatings (dielectric multilayer films), optical characteristics such as the wavelengths and reflectance of reflected light, as well as incident angle dependence, can be adjusted. You can also increase heat resistance with protective films, elevate wear resistance, and choose different metals to adjust electrical characteristics. Customization allows us to skillfully control the balance of functions necessary for our customers' products.

Functions & Mechanisms

Different coatings can be used to create the optimum mirror for your application needs

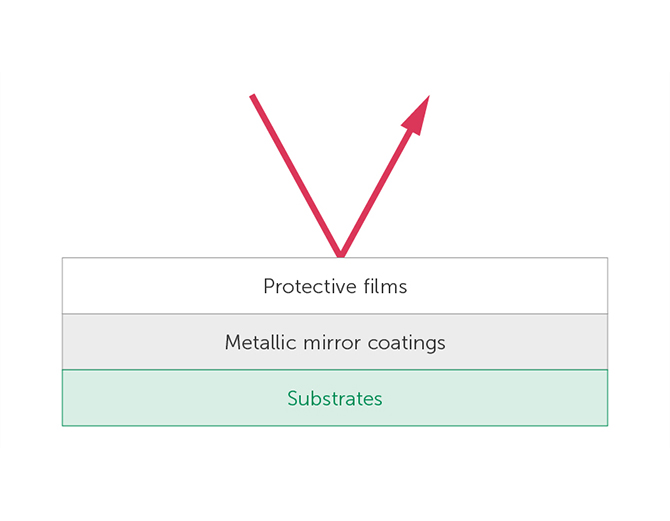

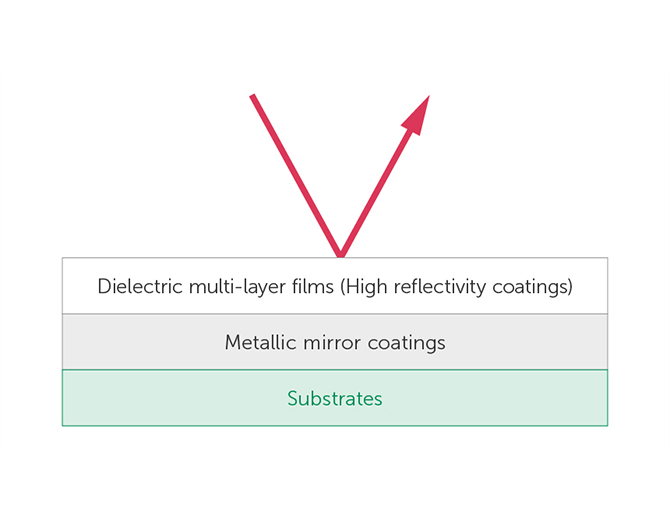

Metallic mirror coatings are formed by applying metal films with a high rate of reflectance to glass and resin substrates. High reflectivity (HR) coatings are metallic mirror coatings with dielectric multilayer film applied to achieve a greater reflectance rate and necessary optical features.

-

Example structure: metallic mirror coatings -

Example structure: high reflectivity (HR) coatings

With high reflectivity (HR) coatings, the reflectance rate is dependent on the incidence angle of light and changes easily. Since they are well suited to applications that involve straight incidence of light, the optimum structure will change, depending on the objective.

When it comes to the manufacture of optimum mirrors for customers, Geomatec has created several metallic mirror coatings and high reflectivity (HR) coatings, developing a wealth of knowledge and achieving firm results.

Applications

Projectors

Brighter and higher quality projector images via skillful manipulation of light

View more applications

Digital signage

Making displays and touch screens easier than ever to see by minimizing reflections and glare

View more applications

Door mirrors

Preventing glare and condensation to ensure clear rear visibility

View more applications

Mirrors around moisture, in locations such as bathrooms or sinks

Making mirrors around moisture, reflect images clearly without clouding.

View more applications

Specifications & Data

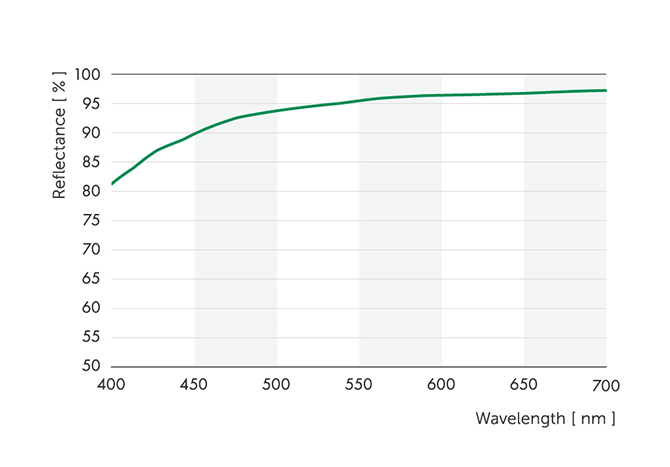

Silver (Ag)

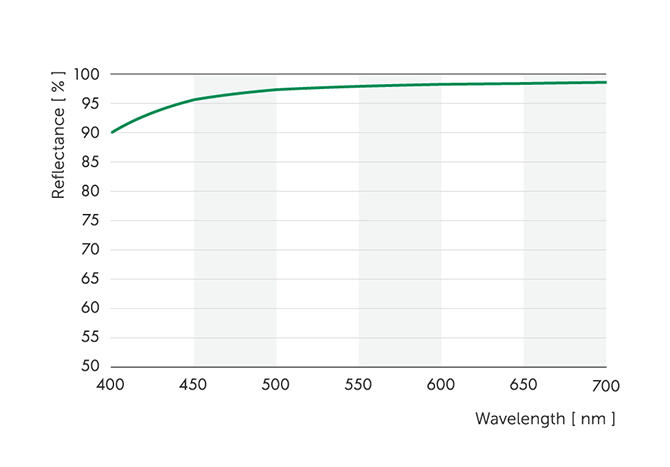

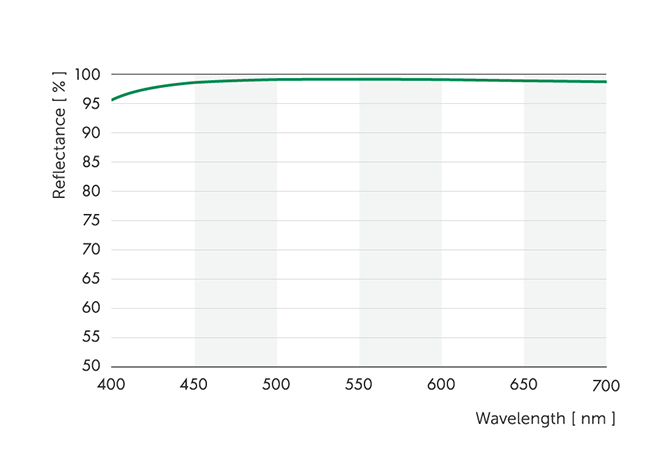

Silver (Ag) is a metallic mirror coating that achieves high visibility and high transmittance of near infrared rays.

-

Reflectance graph showing silver (Ag) + protective coatings -

Reflectance graph showing silver (Ag) + high reflectivity (HR) coatings

Aluminum (Al)

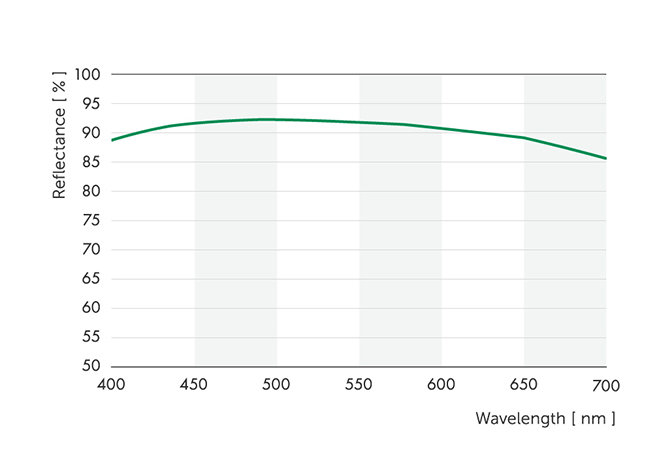

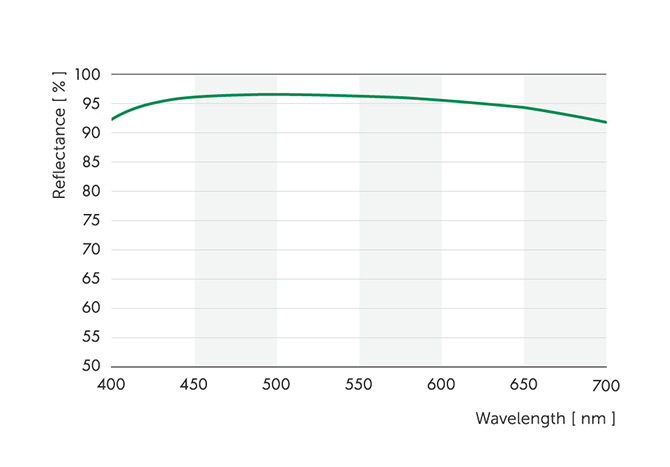

Aluminum is well-suited to the reflection of visible and near infrared light and has been one of the most popular metallic mirror coatings handled by Geomatec since the company's founding.

-

Reflectance graph showing aluminum (Al) + protective coating -

Reflectance graph showing aluminum (Al) + high reflectivity (HR) coatings

Gold (Au)

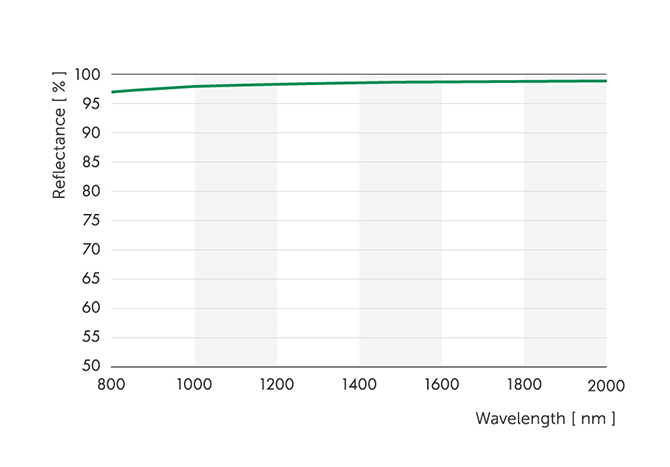

Gold (Au) is a metallic mirror coating suitable for products that require high reflectance of near infrared or infrared rays.

Silver alloy (APC-TR)

When silver (Ag) is converted to an alloy, its resistance to heat is improved.

Contact us-to-Delivery Process

When outsourcing of thin-film coatings to substrates provided by customers

Below is an example of contact us-to-delivery process when outsourcing of thin-film coatings to substrate materials provided by customers. Whether you need a single item prototype or mass production, trust Geomatec to provide high-quality, high-performance thin-film coatings.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Thin-film manufacturing (procurement, coating and post process)

We will apply thin films to substrate materials provided by customers and carry out high-quality, stable manufacturing and processing in a class 100 to 1,000 clean room (as defined in Federal Standard 209D).

-

Step6Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step7Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

When outsourcing of substrate material procurement and post coating process, in addition to thin-film coating

The following is an example of contact us-to-delivery process when outsourcing of substrate material procurement and post coating process, in addition to thin-film coating. Geomatec will control all steps of the process.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Substrate material procurement

Geomatec will procure glass and film substrates from our trusted supply chain, built over several decades of business.

-

Step6Thin-film coating

We will coat your products with the high-performance thin films necessary to achieve your desired functions.

Our class 100 to 1,000 clean room (as defined in Federal Standard 209D) ensures high quality, stable production. -

Step7Post coating process

We handle post coating process for thin film, including surface splicing of glass and frame printing.

-

Step8Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step9Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

Inquiries & Requests for Materials

Please feel free to contact us for more details.

Detailed specifications and data

Detailed specifications and data Prices and Quotes

Prices and Quotes Delivery Confirmation

Delivery Confirmation Customization

Customization Sample and Prototype Production

Sample and Prototype Production Other

Other