For displays & touch screens

Cover Panels

Applicable even to large bendable surfaces, our cover panels minimize background reflection and glare. In pursuit of a more comfortable driving experience

Overview

Cover panels protect the displays and touch panels inside automobiles and aircraft. As the need for display devices with bigger screens or curved glass shapes increases, we respond to the sophisticated needs of each generation and provide a one-stop option for all associated tasks, from the procurement and bending of glass to anti-reflective and anti-smudge coating.

- Point1This unique technology is applicable to not only large cover panels, but also curved forms

- Point2Visible light reflectance less than 0.3%*, making it an anti-reflective coating that offers easy visibility

- Point3Makes it difficult for fingerprints and oils to stain the glass, keeping the material clean

- Point4We offers all steps, from the procurement and bending of glass to anti-reflective coating

- Point5We will provide customization that is optimized to the structure of your display device

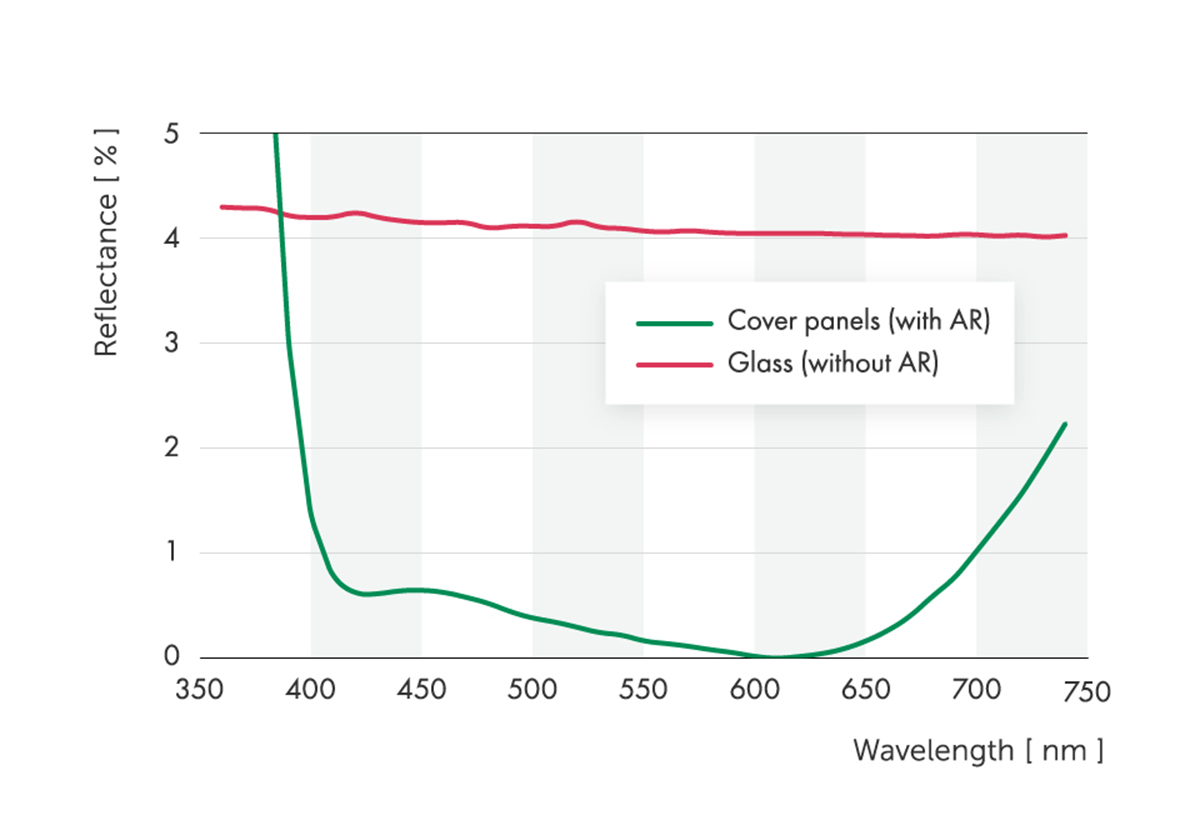

*The rate for normal glass is approximately 4%. Those numbers do not include reflections from the display itself.

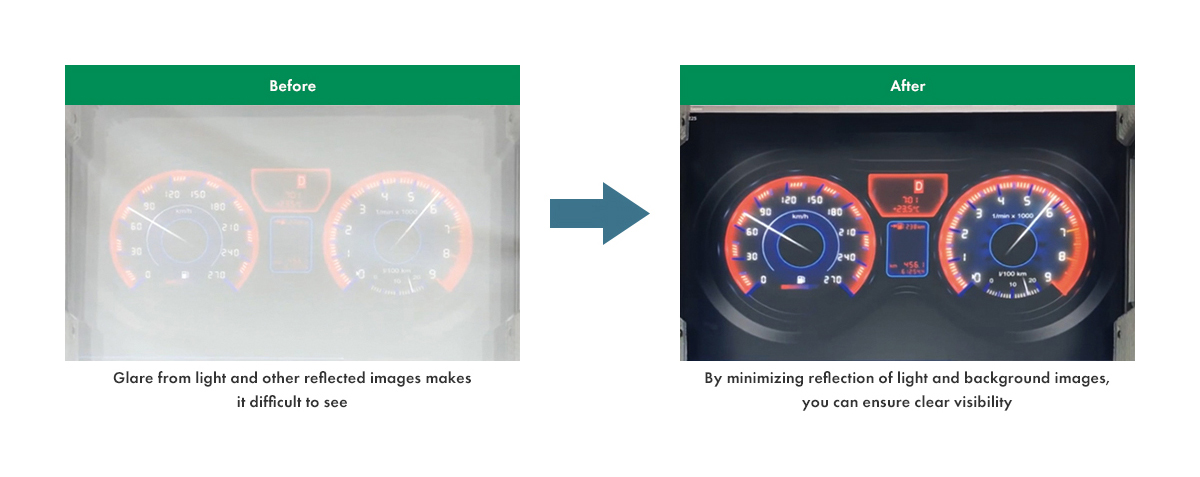

Before & After

This image is a comparison of panels in the same environment, showing those with Geomatec's anti-reflective coating applied and those without anti-reflective coating applied. Take a look at the clear difference and tangible performance levels.

Visible light reflectance less than 0.3%*, making it an anti-reflective coating that offers easy visibility

By using cover panels with Geomatec's unique anti-reflective coating applied, it is possible to reduce the glare and external reflections affecting onboard displays. Doing so increases the visibility of speedometers and car navigation systems, making for a safer and more comfortable driving experience.

Features & Strengths

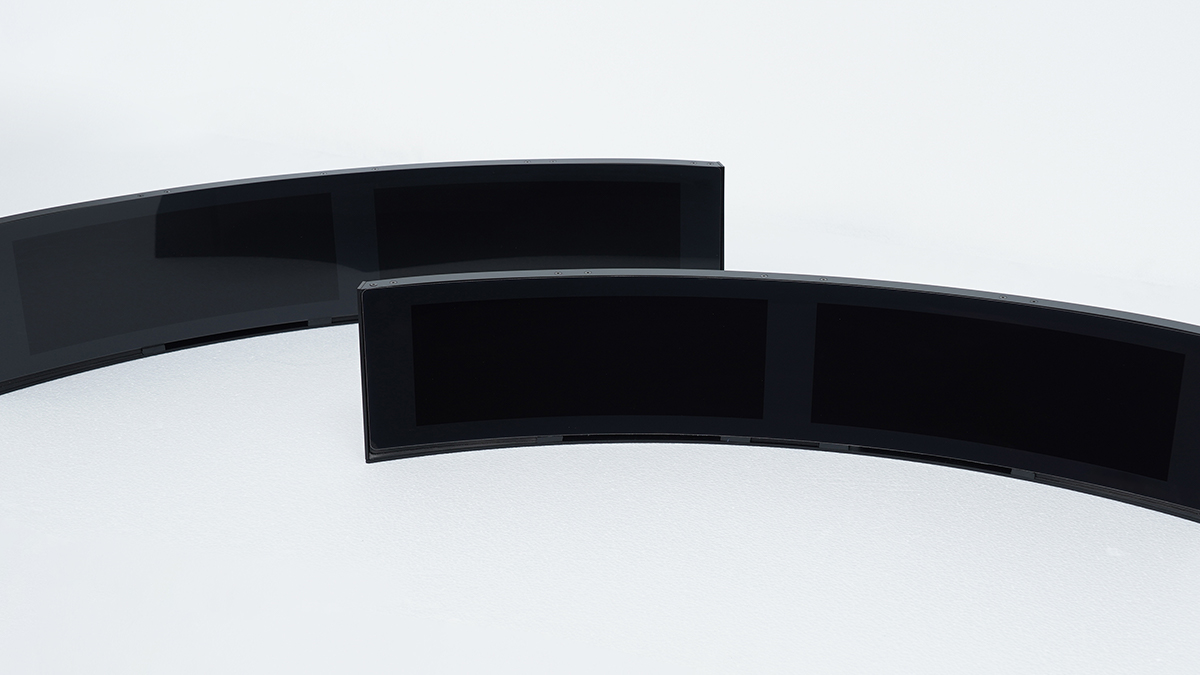

Point1 This unique technology is applicable to not only large cover panels, but also curved forms

In response to the need for display devices with full-screen displays, Geomatec handles the manufacture of large cover panels while also utilizing our unique technology to carry out formation of flat or curved surfaces. This contributes to decorations with a greater design sense and feeling of luxury.

A sample of a curved cover panel manufactured by Geomatec for onboard devices

Point2 Visible light reflectance less than 0.3%*, making it an anti-reflective coating that offers easy visibility

Our position as a specialized thin-film technology manufacturer has enabled us to develop superior anti-reflective (AR) coatings that, when applied to cover panels, are effective at preventing reflection of background images and glare, improving the visibility of display devices.

Point3 Fingerprints or oils stick less, stand out less

Water & Oil Repellent films (Anti-fingerprint & anti-stain coatings) make it difficult for fingerprints or oils to stick to the surface, reducing how much they stand out. When dirt does attach to the surface, it can be removed with gentle wiping.

Point4 We offers all steps, from the procurement and bending of glass to anti-reflective coating

Geomatec covers all tasks with consistently stable production quality, including procurement of glass, printing and bending of black frames, and anti-reflective thin-film coatings. We will take care of everything, from prototype to mass production.

Point5 We will provide customization that is optimized to the structure of your display device

Customization proposals apply to not only the structure of the display devices, but also optical functions such as anti-reflection or repellence of water or dirt, as well as safety, durability, cost, bonding methods, and design.

Structures & Mechanisms

Our optical design achieved by a specialist in thin film, resulting in cover panels with superior visibility

Geomatec's unique anti-reflective cover panels and display modules hold glare to a minimum, while direct bonding (bonding with photoelastic resin) with no gaps makes it possible to reduce reflection of light and realize superior display visibility.

The structure is one where a unique anti-reflective coating is applied to the entire surface of the cover panels, achieving visible light reflectance less than 0.3%

Applications

Automobile display devices

Reflected prevent glare and make displays easier to see

View more applications

Cover panels for aircraft instruments & Displays

Preserve visibility of display devices and maintain normal instrument operation to ensure a safe, stress-free flight

View more applications

Instruments & Displays aboard marine vessels

Maintaining visibility and durability amid harsh environmental conditions, such as exposure to strong sunlight and saltwater

View more applications

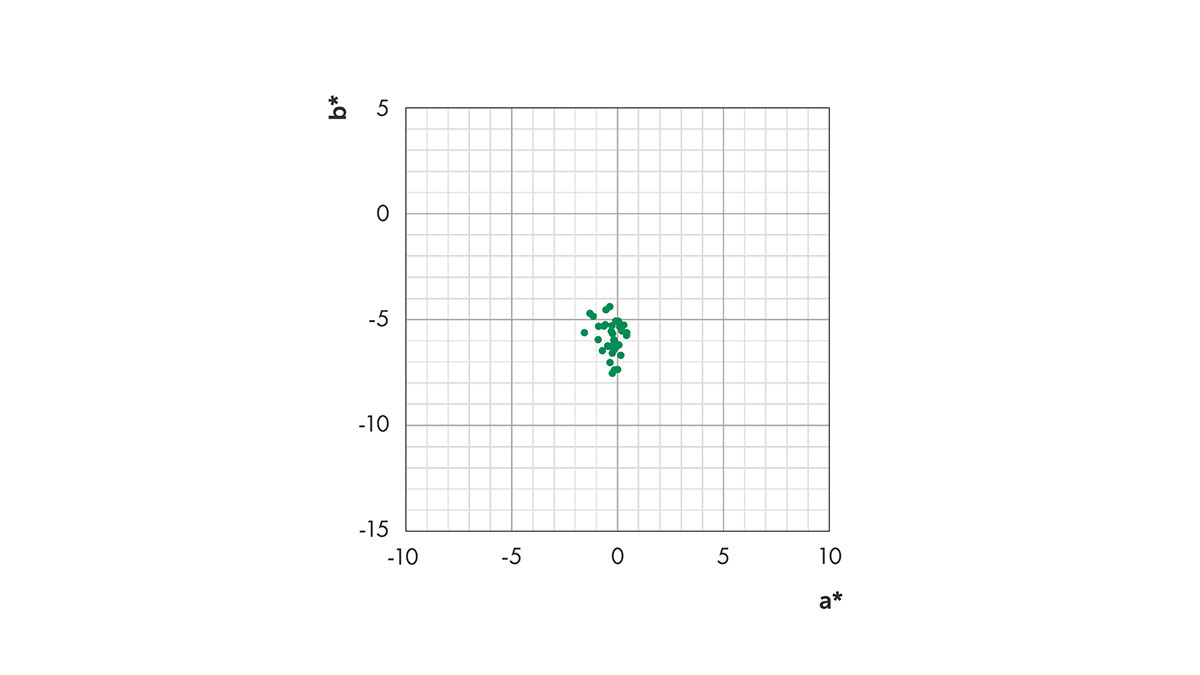

Specifications & Data

Manufacturing examples

| Visual reflectance | 0.2% |

|---|---|

| Color variance range | a* 0±2.5 b* -6±3.5 |

| Substrate materials | Enhanced glass |

| Substrate size | 950 mm x 250 mm |

| Substrate shape | Bendable glass (R1800) |

| Substrate thickness | 0.2 mm |

| Film hardness | 8H or greater |

Contact us-to-Delivery Process

When outsourcing of thin-film coatings to substrates provided by customers

Below is an example of contact us-to-delivery process when outsourcing of thin-film coatings to substrate materials provided by customers. Whether you need a single item prototype or mass production, trust Geomatec to provide high-quality, high-performance thin-film coatings.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Thin-film manufacturing (procurement, coating and post process)

We will apply thin films to substrate materials provided by customers and carry out high-quality, stable manufacturing and processing in a class 100 to 1,000 clean room (as defined in Federal Standard 209D).

-

Step6Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step7Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

When outsourcing of substrate material procurement and post coating process, in addition to thin-film coating

The following is an example of contact us-to-delivery process when outsourcing of substrate material procurement and post coating process, in addition to thin-film coating. Geomatec will control all steps of the process.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Substrate material procurement

Geomatec will procure glass and film substrates from our trusted supply chain, built over several decades of business.

-

Step6Thin-film coating

We will coat your products with the high-performance thin films necessary to achieve your desired functions.

Our class 100 to 1,000 clean room (as defined in Federal Standard 209D) ensures high quality, stable production. -

Step7Post coating process

We handle post coating process for thin film, including surface splicing of glass and frame printing.

-

Step8Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step9Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

Inquiries & Requests for Materials

Please feel free to contact us for more details.

Detailed specifications and data

Detailed specifications and data Prices and Quotes

Prices and Quotes Delivery Confirmation

Delivery Confirmation Customization

Customization Sample and Prototype Production

Sample and Prototype Production Other

Other