Fine electrode patterns

Metal Electrode Films

Optimum structures and materials for various applications, substrates, and electro-conductive characteristics

Overview

We have been making metallic films for over half a century. Take advantage of our know-how, built through the use of all variety of metals.

Features & Strengths

Point1 Abundant know how regarding metallic resource varieties and characteristics, as well as the structure of laminated film

In order to conduct manufacturing that meets the needs of our customers, Geomatec has acquired a wide variety of metallic material resources.

In FPD application, metallic films with low resistance can be combined with ITO for display quality improvement (fine colorization, immediate response time) and other properties. We provide a wide variety of these metallic films.

Point2 Combine with thin-film pattern formation & etching for customization

Applications

Self detection kit

Self detection kits that are useful for in-house medical and healthcare

View more applications

Specifications

List of metallic films

| Materials | Resistance comparison with thin films [µΩ·cm] | Cost | Glass adhesion | Wet etching properties |

|---|---|---|---|---|

| Al | 4 | Low | Average | Good |

| Explanation | - | |||

| Au | 4 | High | Not good | Good |

| Explanation | This material offers low resistance and high durability. Since it display high reflectivity in the infrared range, it is also used in mirrors. It does not adhere well to glass and requires an intermediate layer (adhesive layer). | |||

| Cr | 20 | Low | Average | Good |

| Explanation | Due to its reliability and ability to be processed, this material is extremely easy to use. However, it has high membrane stress and its effects on the environment are seen as problematic. In addition, since its resistance is not so low, it is not appropriate for low resistance specifications. | |||

| Cu | 2 | Low | Not good | Good |

| Explanation |

Since it offers low resistance, this material provides superior electro-conductivity. However, it does not adhere well to glass and membrane oxidation occurs quickly, leading to changes in heat resistance. As such, it cannot be used on it own. Lamination or alloying must be considered. |

|||

| Mo | 13 | Standard | Good | Good |

| Explanation | Resistance is low and it is easily processed. However, it is susceptible to water and there are problems with reliability. | |||

| Ni | 16 | Low | Not good | Average |

| Explanation |

Since it is a magnetic material, it is not suited for spattering, but if target plate thickness is monitored, use is possible. It does not adhere well to glass and cannot be used on its own. Etching is possible with a mixture of phosphoric acid and nitric acid. As such, expectations are high for its use as a protective film with Al alloys and Ag alloys. |

|||

| Ta | 180 | Standard | Not good | Not good |

| Explanation |

This material has superior reliability and is extremely stable. However, it does not adhere well to glass and problems occur with etching. Generally, β-Ta is used, but it is highly resistant. If low resistance is necessary, α-Ta is used. Comparative Resistance

|

|||

| Ti | 70 | Low | Good | Average |

| Explanation | - | |||

| Ag Alloys | Approximately 3.5 | High | Average | Average |

| Explanation |

Since silver alloys are highly reflective and offer low resistance, they are used as anti-reflective conductors. However, they are not susceptible to processing and are highly susceptible to UV rays. As such, use is limited to specific clients, rather than broad adoption. With that said, expectations are high for the material as low resistance products continue to develop. |

|||

| Al Alloys | Approximately 7 | Low | Good | Good |

| Explanation |

This material has comparatively superior resistance and is available at low cost. However, it is extremely susceptible to alkalines, meaning there are problems with reliability. In addition, when the material comes in direct contact with ITO films, the high potential difference between aluminum and ITO leads to galvanic corrosion. |

|||

| Mo Alloys | Approximately 18 | Standard | Good | Good |

| Explanation | These materials maintain the characteristics of pure molybdenum and address some of its problems. Through alloying, the comparative resistance is slightly higher than pure molybdenum. | |||

Contact us-to-Delivery Process

When outsourcing of thin-film coatings to substrates provided by customers

Below is an example of contact us-to-delivery process when outsourcing of thin-film coatings to substrate materials provided by customers. Whether you need a single item prototype or mass production, trust Geomatec to provide high-quality, high-performance thin-film coatings.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

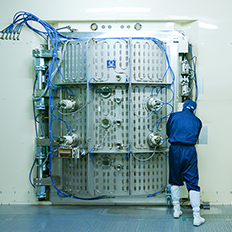

Step5Thin-film manufacturing (procurement, coating and post process)

We will apply thin films to substrate materials provided by customers and carry out high-quality, stable manufacturing and processing in a class 100 to 1,000 clean room (as defined in Federal Standard 209D).

-

Step6Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step7Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

When outsourcing of substrate material procurement and post coating process, in addition to thin-film coating

The following is an example of contact us-to-delivery process when outsourcing of substrate material procurement and post coating process, in addition to thin-film coating. Geomatec will control all steps of the process.

-

Step1Contact Us

For detailed questions regarding our products and solutions, order numbers and specifications, delivery times and budget, areas where delivery is possible, or for any other questions about how we can assist with your objectives and ideas, please feel free to contact us.

-

Step2Discovery & Technical meetings

After inquiring about the details of your request, we will propose the plan that best allows us to meet your objectives. Of course, Geomatec engineers will collaborate with all kinds of manufacturers, as necessary, to support the creation of a product that meets your standards.

-

Step3Estimates

We will quote based on the specifications defined in the discovery & technical meetings.

Please rest assured that information on the intended applications of your product, personal information, or other confidential information we receive will be monitored under a strict information security system. -

Step4Prototypes & Samples

We will produce prototypes and samples as required.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the prototype. -

Step5Substrate material procurement

Geomatec will procure glass and film substrates from our trusted supply chain, built over several decades of business.

-

Step6Thin-film coating

We will coat your products with the high-performance thin films necessary to achieve your desired functions.

Our class 100 to 1,000 clean room (as defined in Federal Standard 209D) ensures high quality, stable production. -

Step7Post coating process

We handle post coating process for thin film, including surface splicing of glass and frame printing.

-

Step8Quality inspection & Shipping preparation

We conduct quality inspections of all the products we provide our customers and provide packing according to strict standards.

Geomatec has acquired certification for its QMS (ISO9001: quality management system) and endeavors to provide safe and stable delivery of high-quality products. -

Step9Delivery

We will reliably deliver our products to any location, by any method, and on any day you specify.

*We offer a flexible range of options other than the above, including in-house consultation on site at customers' factories.

Inquiries & Requests for Materials

Please feel free to contact us for more details.

Detailed specifications and data

Detailed specifications and data Prices and Quotes

Prices and Quotes Delivery Confirmation

Delivery Confirmation Customization

Customization Sample and Prototype Production

Sample and Prototype Production Other

Other

Brochures

Click here to download brochures in PDF format.

Small Lots & Samples

Small lots and sample items can be purchased via the online store.