FAQ

What do you need help with ?

We have gathered here common questions from customers and their answers. If you cannot find an answer to your question here, please feel free to contact us.

About thin films

-

Q.What are the merits of applying thin films?

A.By applying thin films to substrate materials, you can equip the substrates with electrical, optical, and mechanical properties.

Examples include conduction of electricity, division of light into three primary colors, heat generation, and repelling water. By equipping the substrate with new properties using thin films, you can make dramatic improvements in product function. Please visit the page below for further information.

-

Q.What are ITO films?

A.ITO films are thin films used to conduct electricity on surfaces requiring high transparency, such as liquid crystal displays and smartphone touch screens.

ITO stands for Indium Tin Oxide, a mixture of indium and tin oxides. Thin films coated with ITO are both transparent and electrically conductive. They are used in a number of applications that affect your world, such as liquid crystal displays and smart phone touch screens.

As a leader in ITO manufacturing, we can create ITO coatings that with the optimum balance of transparency, electro-conductivity, durability, and flatness desired by customers. Please visit the page below for further information. -

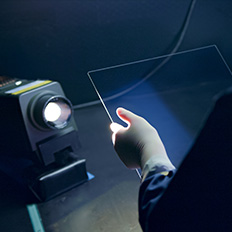

Q.What is film deposition?

A.Deposition is the term for the process by which thin films are coated onto the surface of the materials that will be used as substrates.

By depositing thin films with a variety of properties onto the substrate materials, you can achieve dramatic improvement in product function. In addition, our company is also capable of "vacuum coating", a technique that requires nanoscale control in a vacuum environment.

Please visit the page below for further information on the materials and shapes that can be coated with thin films.

About estimates and orders

-

Q.Can orders be made at the single unit level? Also, how can I request a prototype?

A.We accept orders starting at a single unit. In addition, if you would like to request prototyping, please contact us via the contact form.

As a first step, use the form below to contact us about products. A representative will contact you to confirm the contents of your request.

In addition, if you are also considering mass production at some point in the future, we can process your prototype on the same machinery that will be used for mass production, ensuring a smooth transition into the mass production stage and identical quality and features as those seen in the protype.

About material types, shapes, and sizes

-

Q.What materials can be coated with thin films?

A.Nearly all types of materials can be coated with thin films; not only glass and metal, but also resins, paper and more.

Visit the page below for further information on the substrate material types, shapes, and sizes that can be coated with thin films.

-

Q.What shapes can be coated with thin films?

A.In addition to plates and film rolls, thin films can be applied to a variety of shapes depending on your specifications, including semi-circular and cylindrical (inner and outer) surfaces or those with unique shapes.

Visit the page below for further information on the substrate material types, shapes, and sizes that can be coated with thin films.

-

Q.What size of substrates can be coated with thin films?

A.We pursue the production possibilities based on the shape and coating materials you require. In general, we are capable of handling the following maximum size.

Plates (sputtering) Maximum 1,880 x 1,500 mm Plates (vacuum coating) Maximum 1,000 x 500 mm Film rolls (sputtering) Rolls with a maximum width of 1,300 mm

Maximum length 7,000 m (maximum sizes may vary depending on film thickness)Visit the page below for further information on materials and shapes.

Thin-Film Targets & Substrates

Please let us know what kind of shapes and sizes will work for you. Contact us through the following form.

-

Q.What materials are used for film coating?

A.Please refer to the page below.

Geomatec possesses a rich inventory of over 200 varieties of metals, metal oxides, and semiconductors. In addition, our skills and know-how, built over long years of experience, enable us to not only work with a diverse range of materials but also create layered structures of multiple materials to achieve the properties you require. We also work in tandem with material manufacturers to develop new materials, so that we can meet the many needs of our customers.

About manufacturing system and factory processes

-

Q.Where will manufacturing take place?

A. Depending on the customers' local region or specific requests, Geomatec can conduct manufacturing at any of our facilities in Japan. In addition, please feel free to consult us about working in-house at your location.

With locations in the Miyagi Prefecture town of Kannari and the Hyogo Prefecture town of Ako, Geomatec has plants and facilities that are among one of the world's largest in the field of thin-film manufacturing. Please visit the page below for further information.

-

Q.Please tell me about efforts to achieve ISO (quality, environmental) certification

A.All of our locations have achieved certification for product quality management systems (ISO 9001, JISQ 9001), as well as environmental management systems (ISO 14000, JISQ 14001).

-

Q.What processes can you handle before and after thin-film coating?

A.We handle procurement of substrates such as glass, cutting to size and polishing, and post-coating etching.

At Geomatec, we understand the need to respond to the needs of an increasingly diverse market. We have defined not only thin-film coating, but also cutting to size and polishing of substrate materials, and etching as core skills that we are constantly developing. We have vast experience in the processes that take place before and after thin-film coating and possess systems that can provide high added value to your products. As a first step, please contact us via the form below.

For more questions

If you cannot find an answer to your question here, please feel free to contact us.

Contact Us