High technology and one of the industry’s largest facilities.

High-performance thin films across the globe.

As a manufacturer specializing in thin film technology, Geomatec possesses factories and facilities in Japan that are among one of the industry’s largest. With technology and know how developed over many years of experience with thin films, our technicians use a variety of equipment to handle more than 10,000 projects per year and provide high performance, high quality products to customers around the world.

-

Production & Research Base

3

regions

-

Total floor area (㎡)

41,051+

*production & research base

-

Coating equipment

79

units

-

Number of projects

10,000+

per year

Three locations for Production and R&D

Geomatec’s factories in Japan for thin films

Geomatec’s production and R&D facilities in three locations bring together a variety of connections. Each of our locations has roots in the local region and individual character that can be put to use by customers on their prototypes and mass production.

-

Japan

JapanKannari Factory

With its diverse variety of thin film manufacturing equipment, Geomatec can handle all types of thin-film manufacturing -

Japan

JapanAko Factory

The latest techniques and manufacturing know how for large scale substrate and thin-film production -

Japan

JapanR&D Center (Tokyo)

Geomatec’s R&D center has forged the future of thin-film technology

Kannari Factory

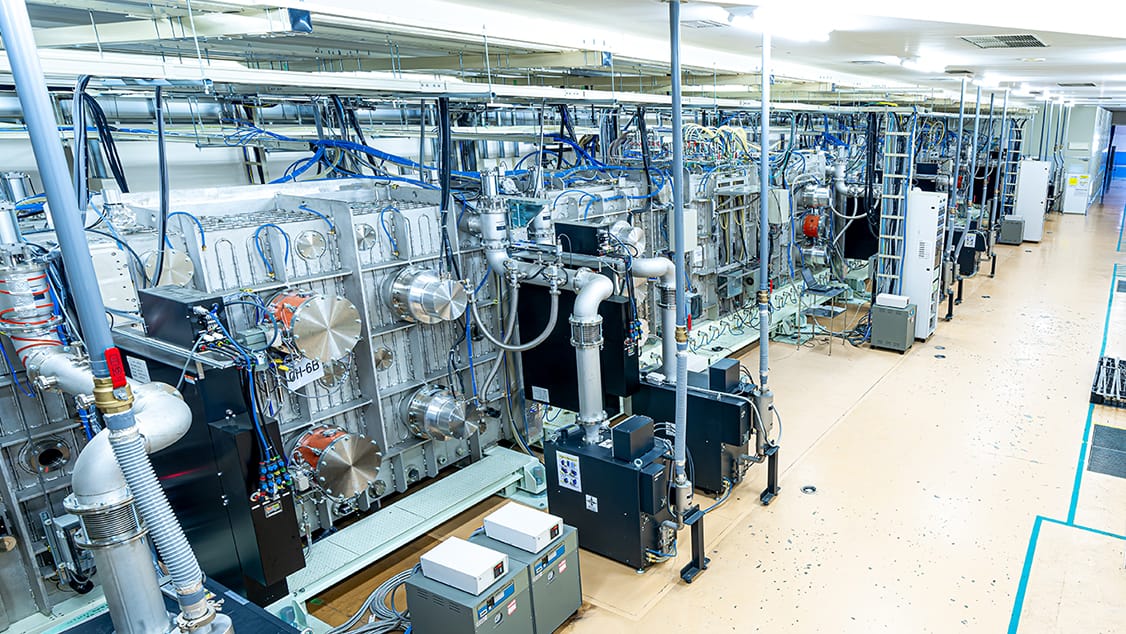

The diverse variety of machinery can handle coatings of all types of thin films handled at Geomatec

At the source of a river that travels down the Ou mountains, Kannari is a rural landscape within Miyagi Prefecture that unfolds with lush greenery and is the hometown of the employees who founded Geomatec’s facilities there in 1975.

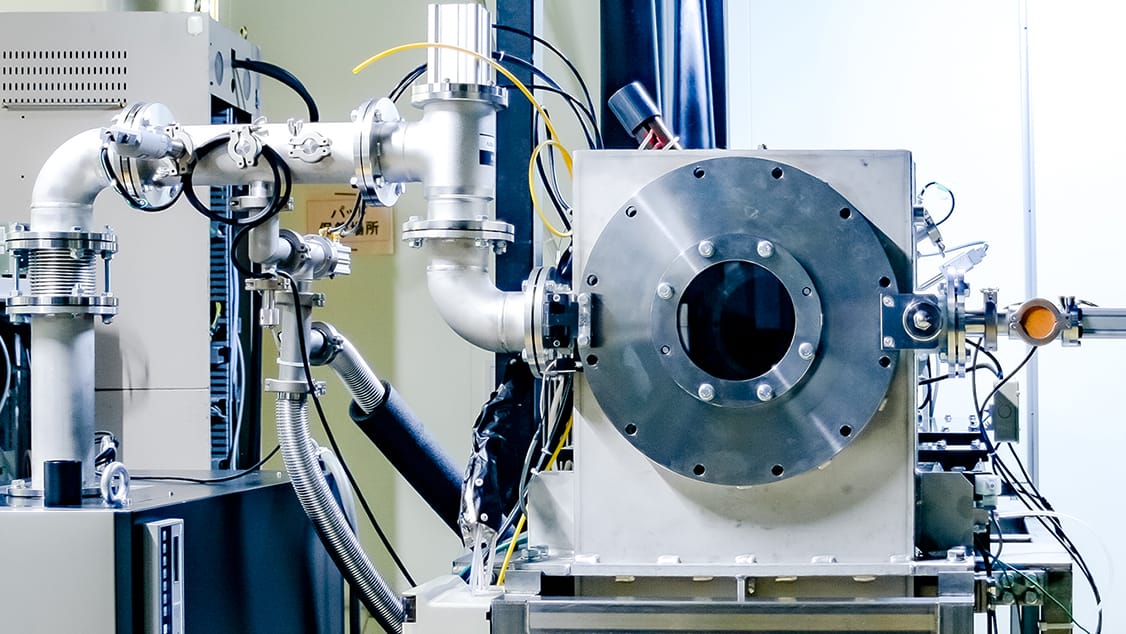

The Kannari Factory has supported Geomatec’s development for several years, possessing several pieces of coating equipment, new and old. Along with the rich knowledge of our technicians, the machinery enables a wide range of thin-film manufacturing processes, from prototype to mass production.

Features

- All varieties of thin-film processing can be handled at Geomatec

- With its diverse range of manufacturing equipment, the plant covers all steps from prototype to mass production

- Possessing special equipment found in only a few places in the world, such as inner-cylinder film coating equipment, this factory can process thin films of various sizes and shapes

Facilitiy data

| Name | Kannari Factory |

|---|---|

| Location | 51 Kinsei Kannari, Kurihara, Miyagi Prefecture, Japan |

| Founded | 1975 |

| Site area | 53,816 ㎡ |

| Total floor area | 23,451 ㎡ |

| Equipment for thin- film coating |

58 units

|

| Clean room | Class 100, Class 1000(Fed. Std. 209 D) |

| Cleaning line | Facilities for cleaning using cleaning liquids and sound waves |

| Inspection line | Inspection upon receipt, electrical inspections, spectral qualities inspections, reliability inspections, etc |

| Certification |

|

Inside of factory

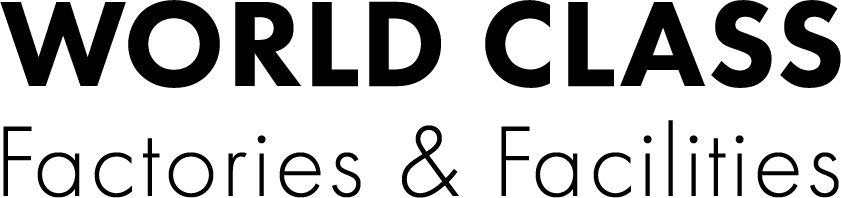

Rare coating equipment for small, medium, and large inner-cylinder surfaces. The photo is of large-sized equipment

The Kannari Factory handles production of a large quantity of thin films for the extremely small components

We possess small format machines suited for small items and prototypes. With so much equipment, new and old, lined up, the room looks a museum of coating equipment

Ako Factory

Handling of large substrates & films

The latest know how in the manufacture of thin films, at your fingertips

Located in the mountains near the shores of the Seto Inland Sea and surrounded by lush natural scenery, Ako is situated on a strong foundation resistant to earthquakes and rich with the ample water needed for cleaning work. It has also been selected as the location for Geomatec’s newest cutting edge factory.

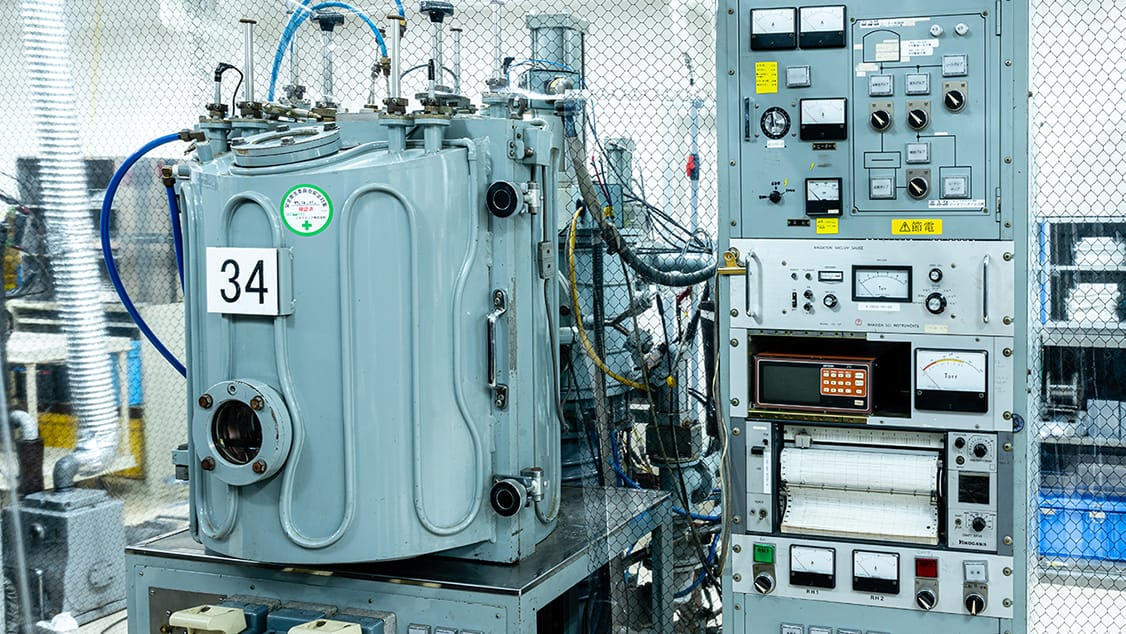

The Ako Factory was designed with mass production and includes robots arms capable of repeatedly receiving and passing large glass plates, as well as roll to roll machines capable of handling massive film rolls 1,300 mm in width and over 20 m in depth. Rounding out the facilities are batch-type machines totaling phi 3,000. All in all, there are several options for the mass production of thin films.

Features

- Equipped with high precision robot arms utilized for automated manufacturing, this factory includes our largest line of machines for inline sputtering, a method with high production efficiency for not only single orders, but also mass production

- The factory possesses three roll to roll sputtering units, two of which can be used with areas as wide as 1,300 mm

Facilitiy data

| Name | Ako Factory |

|---|---|

| Location | 1325-80, Kizu Inariyama, Ako, Hyogo Prefecture, JAPAN |

| Founded | 1992 |

| Site area | 46,478 ㎡ |

| Total floor area | 15,848 ㎡ |

| Equipment for thin- film coating |

15 units

|

| Clean room | Class 1000(Fed. Std. 209 D) |

| Cleaning line | Facilities for cleaning using cleaning liquids and sound waves |

| Inspection line | Inspection upon receipt, electrical inspections, spectral qualities inspections, reliability inspections, etc |

| Certification |

|

Inside of factory

The machines handle giant film rolls up to 1300 mm in width, with depths of up to 20 m or more

The high-precision robot arms continually receiving and passing on large, thin glass plates is dynamic and powerful

Our equipment for the inline sputtering method is among one of the largest in Japan, capable of mass production over large-area surfaces

3,000Φ equipment within a clean room. capable of being set with multiple substrate materials

R&D Center (Tokyo)

Geomatec’s R&D Center,

where the future of thin-film technology is forged

The Ota-ku region of Tokyo home to Geomatec’s R&D Center is connected to Tokyo Bay and the Tama River, making it one of Japan’s primary neighborhoods for industry with over 3,000 factory nearby, as well as manufacturers with technology that continues to astonish the world.

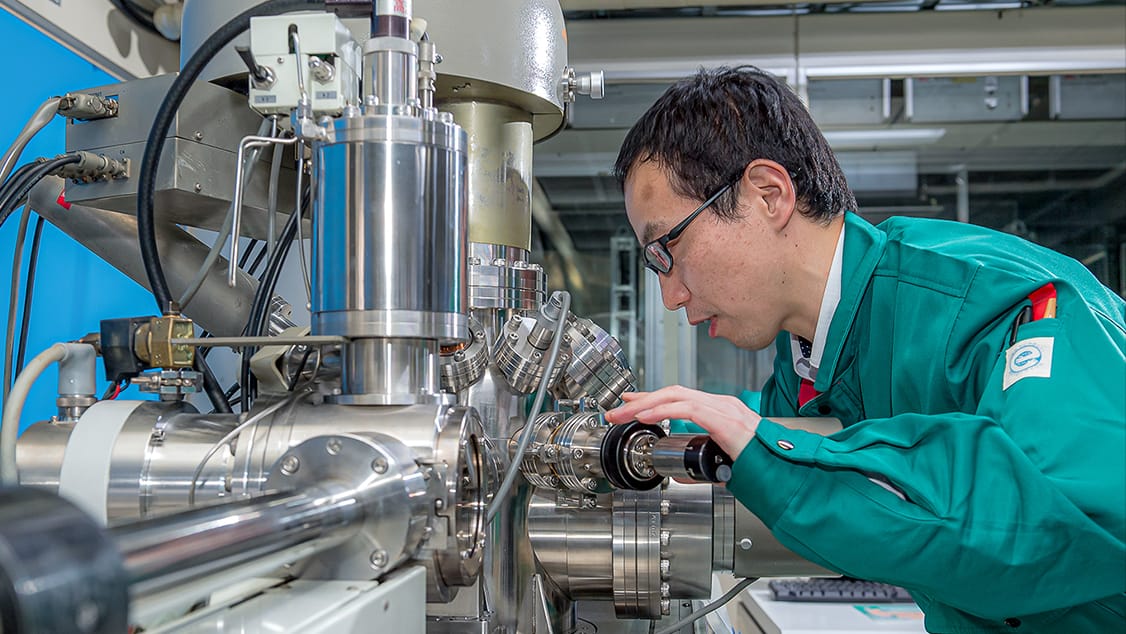

Gathering the full strength of Geomatec’s technology, accumulated from the time of its founding in Tokyo in 1953 to the present, we engage daily with the development of thin-film technology and conduct R&D into the thin-film products and materials that will support the next generation.

Features

- R&D center supporting Geomatec’s high-performance thin-film technology

- Region well-suited to the development of next-generation technology and thin-film materials, as well as technical consulting, prototyping, measurement, and analysis necessary for the improvement of existing products

- This means not only thin-film coatings, but also abundant know how regarding post coating processes such as photolithography (patterning, etching). By combining the knowledge of both areas, we continue generating technological innovations

Facilitiy data

| Name | R&D Center (Tokyo) |

|---|---|

| Location | 3-13-7 Yaguchi, Ota-ku, Tokyo JAPAN |

| Founded | 1990 |

| Site area | 878 ㎡ |

| Total floor area | 1,752 ㎡ |

| Equipment for thin- film coating |

6 units

|

| Clean room | Class 1000(Fed. Std. 209 D) |

| Cleaning line | Facilities for cleaning using cleaning liquids and sound waves |

| Inspection line | Inspection upon receipt, electrical inspections, spectral qualities inspections, reliability inspections, etc |

| Certification |

|

| Notes | We have many units of machinery for the measurement and analysis of thin film, its properties, and its condition |

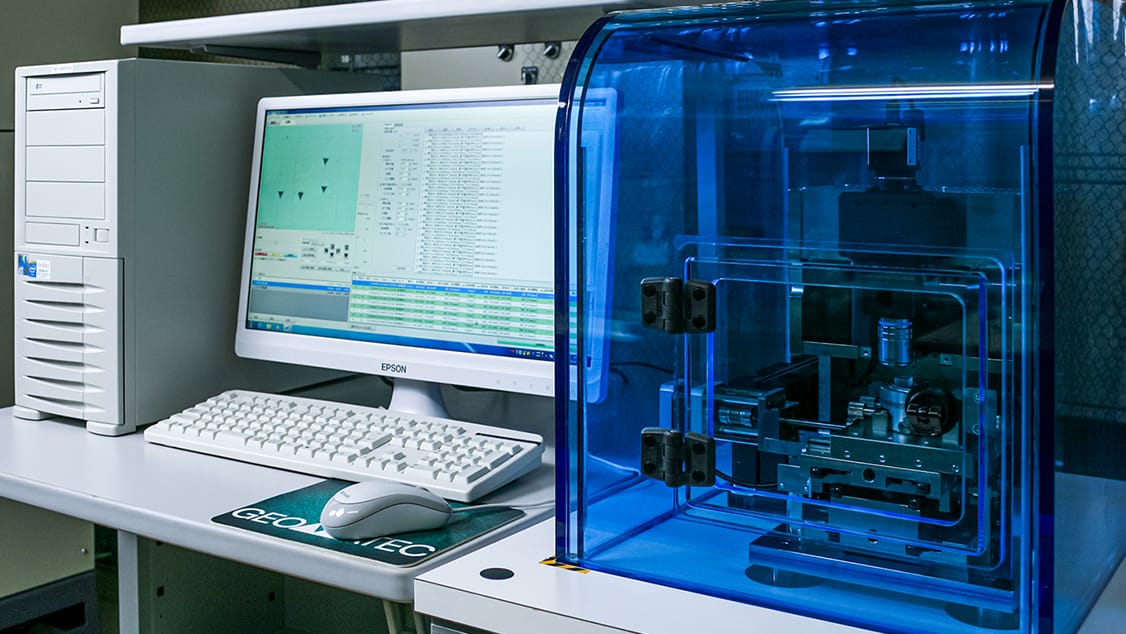

Inside of center

Setting the coating conditions for the sputtering equipment. We will use our abundant knowledge to find the optimum solution from among a large number of conditions.

Measuring the strength of thin film. We will choose the proper analysis equipment to match the needs of your application, selecting from among a wide range of measurement methods.

By analyzing how the composition of the thin-film changes with coating conditions, we confirm whether the sought after coating has been achieved.