News

- News

Our office is closed from December 30 to January 8, 2024(JST). Our response will be delayed during the period. We will get back to you after we resume our business on January 9, 2024. Sincerely apologize for the any inconvenience this may have caused you.

- News

Transparent film heaters are now available in Geomatec online store.

- News

Our office is closed from August 11 to August 20, 2023(JST). Our response will be delayed during the period. We will get back to you after we resume our business on August 21, 2023. Sincerely apologize for the any inconvenience this may have caused you.

- News

GEOMATEC Global Online Store is now open!

- News

Introducing Featured Articles in TIME Magazine Asia Edition (March 27-April 3 issue)

GEOMATEC - High-Performance Thin-Film Technology Company

Geomatec is a manufacturer specializing in thin-film technology. It is headquartered in Yokohama, one of Japan' s most prominent international port cities. Since the company' s founding in 1953, we have consistently refined our thin-film technology, enabling breakthroughs for companies in a wide variety of industries and fields across the globe.

Featured Topics

-

[Customer Report] Transparent conductive film for solid-state dye-sensitized solar cells

The future of sustainable energy: the next generation of solar cells

- Learn more

-

Roll-to-roll film formation

This film formation method enables mass production of flexible thin film in rolls. For production of flexible devices such as solar cells and 5G antennas.

- Learn more

-

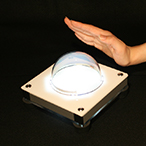

[Customer Report] Transparent Heater for LiDAR Outer Cover

A wide range of thin film solutions that contribute to the evolution of sensing devices.

- Learn more

-

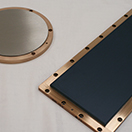

Feature: Thin copper (Cu) film

The price of copper is soaring due to increasing demand. Find out about some of the ways our thin copper (Cu) film is used.

- Learn more

-

Next gen. moth-eye-inspired coating film g.moth™

Super anti-reflective, super water repellent. Greater transparency and visibility than ever before

- Learn more

-

Transparent Heaters - Heating without any obstruction to visibility

Heat retention, defogging, and defrosting functions for equipment that also requires transparency, such as on-board cameras

- Learn more

-

Inorganic High-Resistance Transparent Conductive Films

Transparent films with a resistance greater than 1kω/sq have upturned conventional wisdom

- Learn more

Products & Solutions

Control of multi-layered films.

New levels of functions.

Geomatec' s high-performance thin film provides our customers' products with coatings so thin, there are almost invisible. Using this membrane-like coating, products can be fit with a number of functions, such as anti-reflective, water-repellent, or anti-static properties. The film can also be applied in multiple layers (in some cases as many as 100 or more).

Applications Our thin-film technology can expand in an unlimited range of applications

In modern society, thin-film technology has become almost indispensable and is used in many of the devices that populate your daily life. Uses for this technology continue to grow, and Geomatec knows just how to employ this power to bring your ideas to life.

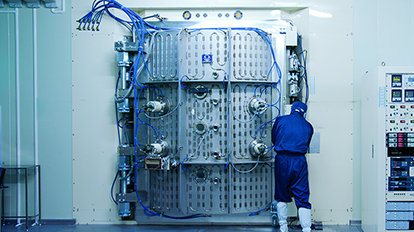

TechnologyThe history and forefront of thin-film technology at your fingertips

Geomatec was founded in 1953 and since then, we have been a leader in thin-film technology, sharing our wealth of knowledge with subsequent generations of technicians. Our factories and facilities are among one of industry's largest and are capable of handling every step of the process, from R&D to mass production. Harnessing the power of thin-film technology, we continually produce the breakthroughs that help make customers' ideas a reality.

Who We Are GEOMATEC - High-Performance Thin-Film Technology Company

Whether you' re looking for technical consulting, technical licensing, prototypes or mass production, in the field of high-performance thin film, Geomatec is the answer.

-

Founded in 1953 70 years

-

Employees 389 March 31, 2023

-

FY2022 net sales 5.812 billion yen

-

Number of projects 10,000+ per year

News & Events

- News

Our office is closed from December 30 to January 8, 2024(JST). Our response will be delayed during the period. We will get back to you after we resume our business on January 9, 2024. Sincerely apologize for the any inconvenience this may have caused you.

- News

Transparent film heaters are now available in Geomatec online store.

- News

Our office is closed from August 11 to August 20, 2023(JST). Our response will be delayed during the period. We will get back to you after we resume our business on August 21, 2023. Sincerely apologize for the any inconvenience this may have caused you.

- News

GEOMATEC Global Online Store is now open!

- News

Introducing Featured Articles in TIME Magazine Asia Edition (March 27-April 3 issue)