GEOMATEC to build new mass production techniques for high-performance film with moth-eye structure by the development of distinctive transfer plates

NewsAugust 21, 2018

With the objective of increasing the mass production efficiency and potential size of high-performance film with moth-eye structure, Geomatec has worked in tandem with Tokyo University of Science to develop a new manufacturing technique that employs special transfer plates adapted our original coating technology.

1. Technical Background

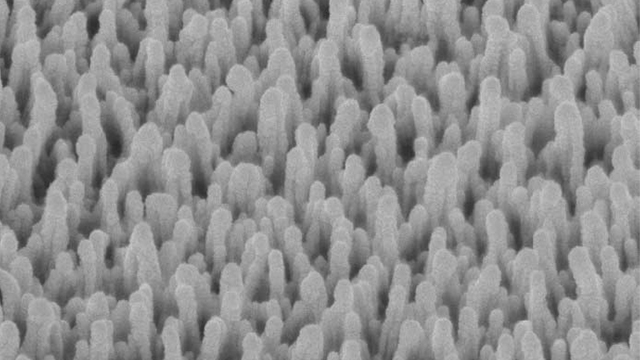

Film with moth-eye structure has a surface made with refined nano-protrusions that are smaller than the wavelength of light. In addition to holding reflective light to a bare minimum, it also gives water-repellency and oil-repellency on the surface. When the film is placed on display equipment, it helps reduce glare and fingerprint stain, enabling sharper imagery. In the future, we plan on adapting the film for a wide range of display and exhibition equipment.

The standard manufacturing process for film with moth-eye structure involves the pressing of film to a transfer plate with nano-sized protrusions to create an uneven structure.

Meanwhile, production of transfer plates traditionally utilizes an aluminum anodization process, but high costs and upsizing have remained difficult challenges.

By working with Tokyo University of Science to develop a production process that employs special transfer plates adapted our original coating technology, a technique that is uniquely suited to large-scale surfaces and high-volume manufacturing, Geomatec has succeeded in optimizing the mass production of film with moth-eye structure.

The newly developed transfer plates are composed with the nano-sized protrusions formed by ion beam-etching their thin-film coated surfaces. This enables us to expand applications to a wider range of base materials as substrates, not only glass but including silicon, metals, and more. (Patent pending).

2. Future Expansion

The new film with moth-eye structure produced through this process will be sold under the name "g.moth™".

3. Future Outlook

At present, the release of this technology will have only a minor effect on earnings. If, at any point, it becomes necessary to revise earnings estimates, we will quickly move to disclose relevant information.

Reference

-

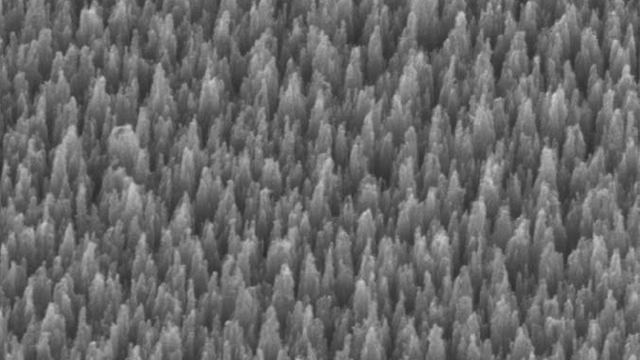

1.Surface Composition of Transfer Plates & Film with Moth-eye Structure

-

Surface Composition of Transfer Plates

-

Surface Composition of Film with Moth-Eye Structure

-

-

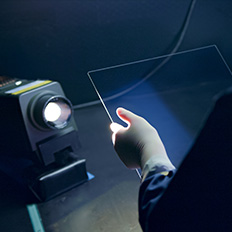

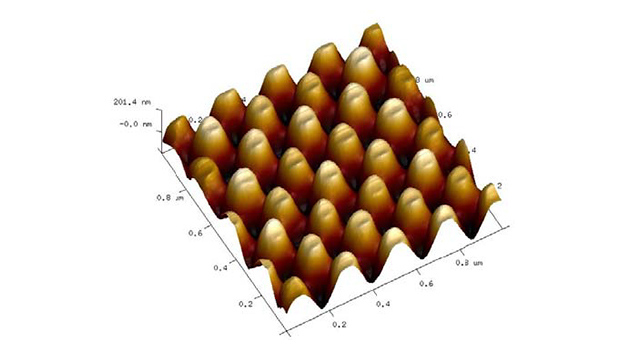

2."g.moth™" Products

-

Moth-eye Structure

The film is formed with nano-sized protrusions that imitate the mechanisms of a moth's compound eye. -

Water Droplet Contact Angle

Thanks to its super water-repellent processing, the surface repels water droplets.

-

Inquiries

Please feel free to contact us for any further questions.

Contact Us